Contact us:

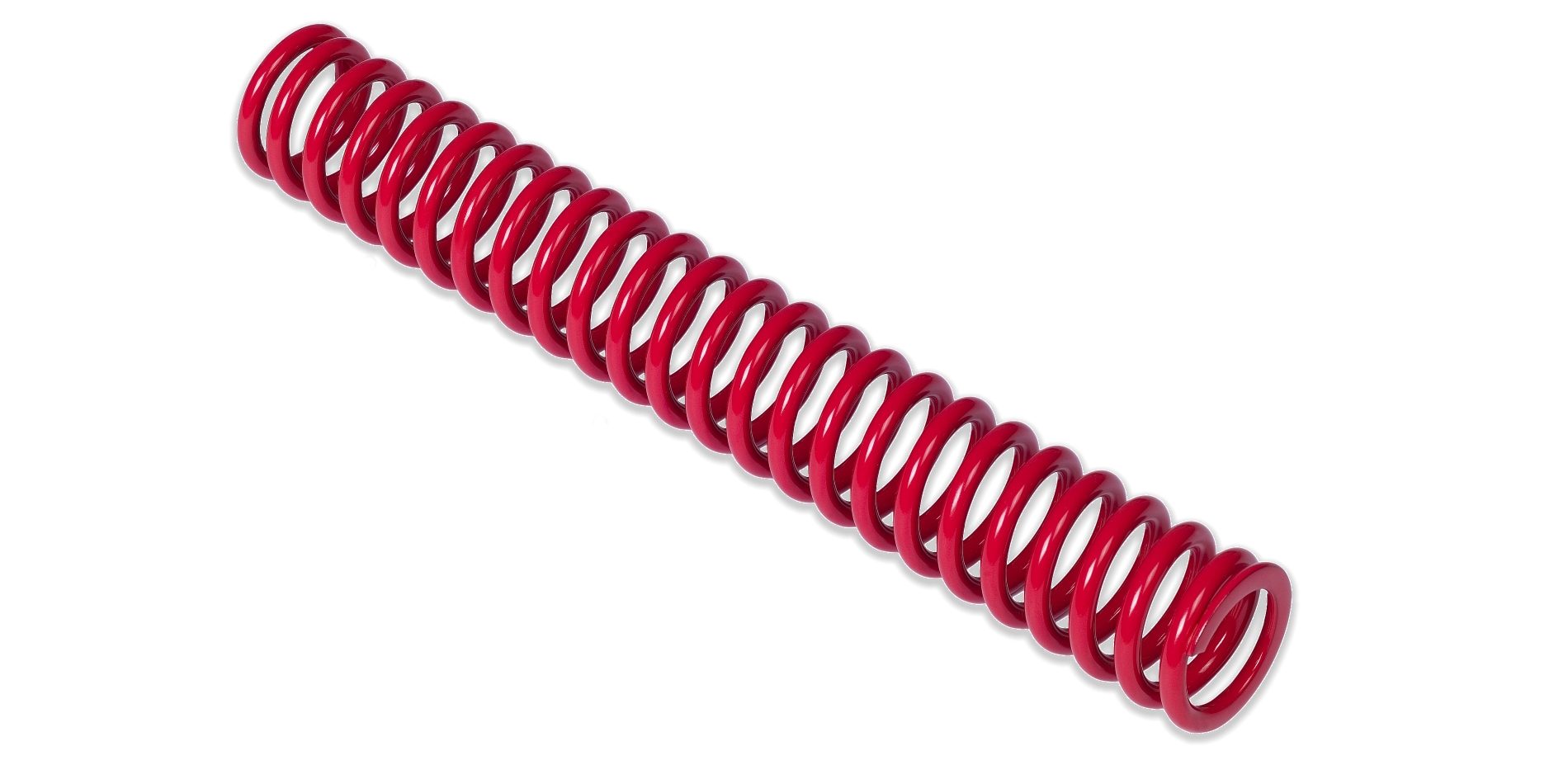

Compression springs

PIERON develops and manufactures high-quality compression springs for high static and dynamic loads. Working closely with our customers' development departments, we create customized spring solutions that are precisely tailored to the respective application. State-of-the-art manufacturing technologies ensure the highest level of quality thanks to a high degree of automation. Specialized measuring and testing equipment enables comprehensive quality controls – for compression springs that function reliably even under extreme conditions.

Specialties

- Dynamically highly loaded compression springs

- Statically highly loaded compression springs

- Small relaxation values through heat treatment

- Fully automated contact pressure and strength testing

- Narrowest of strength tolerances

- Packing and assembly together with other components

- Special packaging available on request

- Model production on short notice

Areas of use

- Automotive

- Mechanical engineering

- Electrical motors

- Control technology

- Measuring technology

- Drive technology

- Brake & safety systems

- Sports & recreation industry

Dimensions range

- Wire diameter: 0.2 – 8.0 mm

- Spring length up to 1500 mm

- Special profiles available

- Outer diameter max. 120 mm

- Shape of springs available on request

Material

- All spring materials

Surface coating

- Spring steel wires with common industry coating

- Phosphating in-house

- Stove enamelling in-house

- Further surface coatings by external service providers

Let's make a difference together!

You have not found your product and are looking for a partner who thinks big together with you? Our experienced engineers help you with your project. Simply make an appointment for consultation!

PIERON Compression springs – FAQ

A compression spring is a mechanical component (design element) that stores energy when subjected to axial load and releases it again when the load is removed. It is one of the most important types of spring used in mechanical and plant engineering and is applied wherever forces need to be cushioned, damping generated or movements controlled. A compression spring typically consists of a spirally wound wire that is compressed when force is applied. The spring's restoring force then ensures that the component returns to its original shape.

We manufacture compression springs with wire diameters ranging from 0.2 mm to 10.00 mm.Our particular expertise lies in the 2 to 6 mm range - precisely where high technical precision and resilience are required. PIERON combines decades of experience with state-of-the-art manufacturing technology to deliver reliable solutions for every application. Especially with custom-made compression springs, our customers benefit from maximum flexibility in both design and functionality.

We design Compression springs to fully exploit their maximum performance within the framework of application standards .In close cooperation with specialized spring wire suppliers, we develop customized special materials (wires) precisely tailored to the requirements of the intended application. This ensures that full functionality is reliably maintained even under the most demanding conditions.

PIERON compression springs are used across a wide range of industries in demanding technical environments. Typical application areas include:

- Automotive

- Mechanical and plant engineering

- Electrical motors

- Control and measuring technology

- Drive technology

- Brake and safety systems

- Sports and recreation industry